Paper tissue is our daily life necessity.

Sometimes take one sheet whenever you need it.

Very convenient.

Because of the huge consumption.

Lots of people stock up on cheap and affordable products.

In China, many paper tissue sell RMB9.9(USD1.38) free shipping on line. Or RMB1.0 per second.

Even get free advertisement paper tissue on the way.

Many people think this is saver way.

They don’t know they are acturally expend their health.

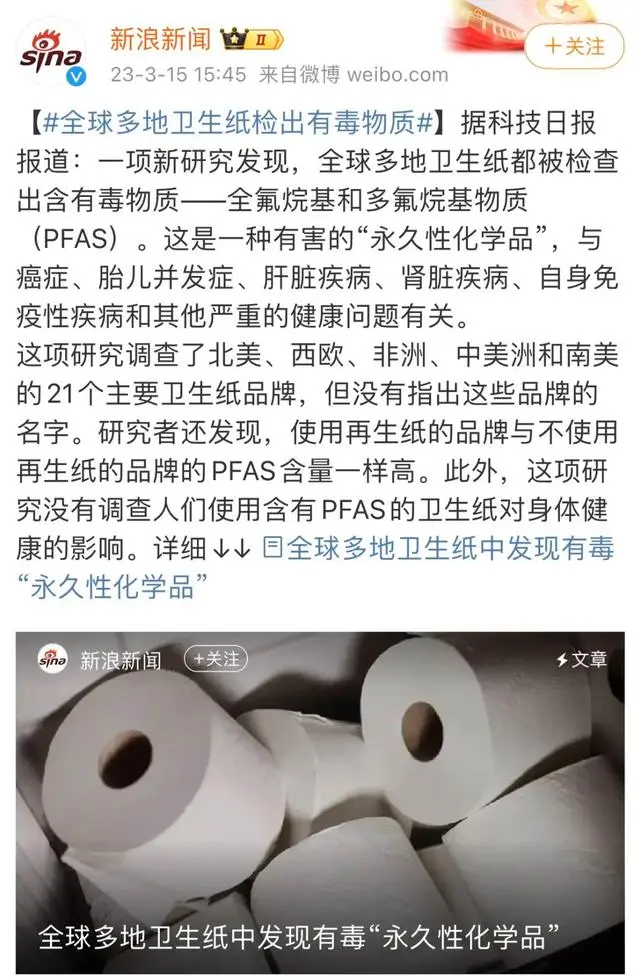

Mar.15,2024 “toxic tissue” being exposed, have you ever used it?

In 2023. According to the 《Science and Technology Daily》 report, Have research found that, Many country barthroom tissue after test contain toxic substances perfluoroalkyl and polyfluoroalkyl(PFAS), And PFAS may increase the incidence of various cancers such as lung cancer and bowel cancer add 59% and may even reduce femail fertility by 40%.

As early as 2019, CCTV 《Weekly Quality Report》 column has done a survey on household paper, in 150 batches oof tissue paper and toilet paper samples,35 batches were unqualified, and the unqualified rate reached 24%.

Among them,9 batches toilet tissue bacterials colonies exceeded the national standard by 13 times.

Some bad suppliers will use recycled incomplete life garbage, such as: waste paper,rags,rotten gauze,etc as raw material, through the illegal addition of a large number of fluorescent whitening agent,industrial talc powder, etc, to make tissue more soft, and sell better.

“Toxic tissue” have any dangers?

Unqualified” toxic tissue” may cause damage for whole body:

Cause skin allergy

Cause intestinal diseases

Causes urological/gynecological diseases

Damage the nervous system,blood system

Safety paper, learn to read the label.

Each of us is the first person responsible for their own health, usually, it is best not to buy cheap tissue.

But if you want to buy reliable paper, it is not necessarily the more expensive the better.

①Carefully to identify the raw material.

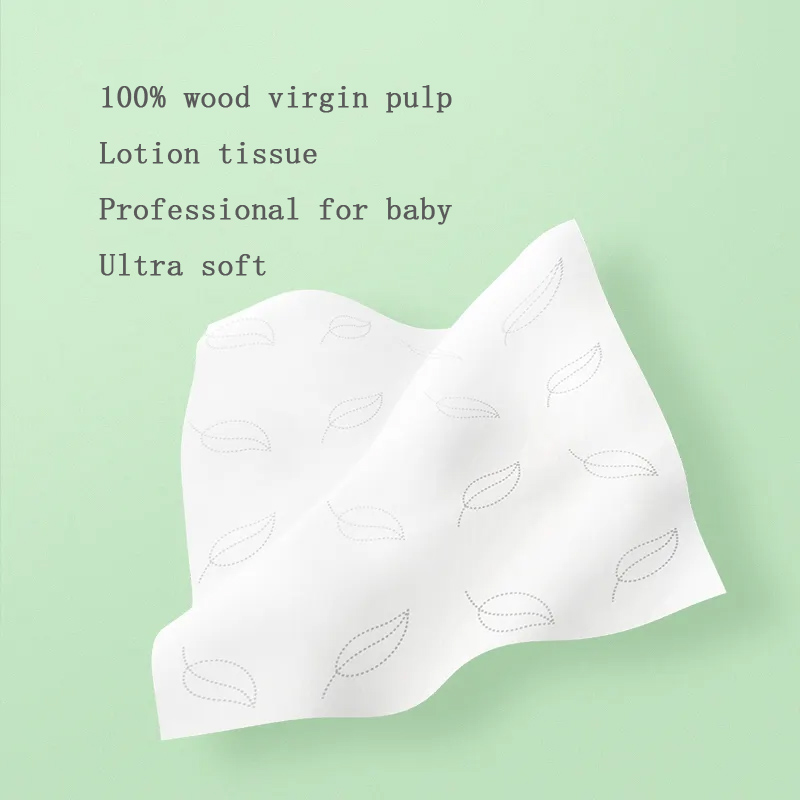

The raw materials of paper tissue are generally virgin wood pulp paper,wood pulp paper,pure wood pulp,virgin bamboo pulp paper,pure bamboo pulp, through this data,paper quality can be distinguished.

Virgin wood pulp paper: refers to totally natural wood to made pulp paper. This kind of pulp has a higher fiber content,the paper produced is delicate and soft, and the quality is higher.

Wood pulp paper: Refers to the pulp of natural plants, including but not limited to wood pulp,grass pulp.etc. The quality of paper tissue is lower than virgin wood pulp paper.

Pure wood pulp: Refers to the pulp all come from wood, but it may be recycled original wood pulp.waste paper pulp.etc. The quality is a little bit poor.

Virgin bamboo pulp paper: refers to totally natural bamboo to made pulp paper. This kind of pulp has a higher fiber content,the paper produced is delicate and soft, and the quality is very higher.

Pure bamboo pulp: Refers to the pulp all come from bamboo, but it may be recycled original bamboo pulp.waste paper pulp.etc. The quality is a little bit poor.

②Look at the quality grade

The higher quality level of paper, the better, that is, excellent products > first-class products > qualified products.

In short, the implementation of the standard is the “bottom line” of the tissue,and those who meet the standard can generally be assured of use.

The raw materials and quality grade is the standard to judge the quality of tissue paper, the better the raw materials, the higher the quality grade, the better the quality of paper tissue.

If you are worried about business counterfeiting, selling counterfeit, counterfeit product information, you can also identify the quality of paper through your own experience, there are the following characteristics to check:

1、Look at the appearance

Take a look at the master packaging, the selection of toilet paper should first check the master packaging. The packaging and sealing of the product should be neat and firm, without damage; The packaging should be printed with the name of the manufacturer, production date, product grade (excellent product, first-class product, qualified product)

Second, look at the appearance of the paper, the paper surface should be clean, there should be no obvious dead folds, mutilations, damage, hard blocks, raw grass, pulp and other paper diseases and impurities, the paper should not be used when serious hair, powder, paper should not be residual printing ink.

2、Look at the brightness

The product whiteness of paper tissue standard A and other products is stipulated to be 85.0% ~ 90.0%, and the normal color of paper tissue should be ivory white and natural white.

Toilet paper is not the whiter the better, it may be added to the excessive fluorescent bleach. Fluorescent agent is the main cause of dermatitis in women, long-term use may also cause cancer.

How can you tell if there’s too much fluorescent bleach?

First of all, it should be natural ivory white with the naked eye, or put the toilet paper under the irradiation of ultraviolet light (such as a banknote detector), if there is blue fluorescence, it proves that it contains fluorescent agents. Although the brightness is too low, it will not affect the use of toilet paper, but it shows that the raw materials used are poor, and try not to choose such products.

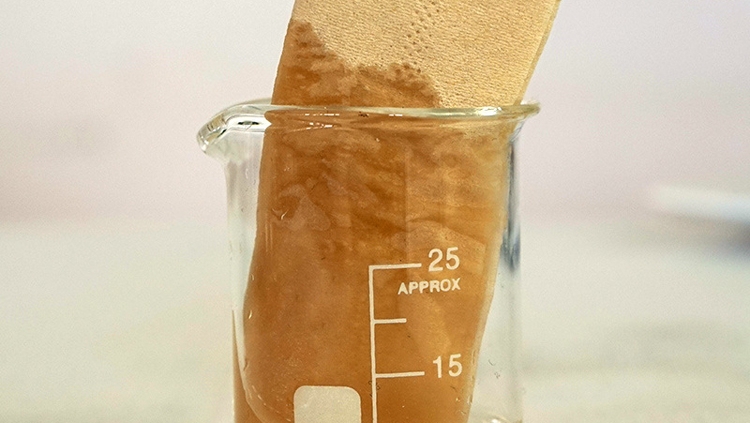

3、Look at absorbency

Can drop water on the paper tissue to see how the absorption rate is, the faster the speed of water absorption, the better.

4、Look at water solubility

Tear off a part of the paper tissue, hang it on the coffee spoon and immerse it in water. After 10 seconds, remove it. Pull down the paper tissue with your left hand to test the strength of the paper tissue after wet water.

Good paper tissue have high density and toughness, and will not be deformed and loose even if soaked in water; And poor quality paper tissue soaked in water, it is easy to loose open.

5、CD Tensile Stength

It is how tough the paper is and whether it is easy to break when used. Pure wood pulp paper because of the long fiber, so the tension is large, toughness is good, not easy to break. Pull the paper towel a little harder, the good paper towel will be pulled wrinkles appear, but will not break. And bad paper towels due to the low content of wood pulp, poor flexibility, a little force will appear fracture phenomenon.

6、Softness

This is an important indicator of toilet paper products, good toilet paper should give people a soft and comfortable feeling. The main reasons that affect the softness of toilet paper are fiber raw materials and wrinkling process. Generally speaking, cotton pulp is better than wood pulp, wood pulp is better than wheatgrass pulp, and toilet paper with excessive softness feels rough to use.

7、Observe combustion

Normal qualified paper tissue are naturally gray after burning, and the paper with excessive fluorescence agent or gum is white or black after burning with fire.

If it is a paper tissue made of pure wood pulp, it should be able to burn completely, if the paper tissue is not clean, then it is likely to add some other things, such as waste paper (waste paper originally has chemical substances). So easy to burn paper tissue will be better in quality.

Generally, the burning of good paper tissue will release light smoke like the burning of wood. If the burning has a pungent smoke smell or black smoke, it is the addition of organic matter. However, the 11 samples in our experiment all emit white smoke, so the raw materials are still relatively good.

If organic matter is added to the paper tissue, then the burned paper ash is easy to stick to a piece, and if the paper tissue is made of pure wood pulp, the paper ash is relatively clean and not sticky.

8、Dust

Popular point is how much dust on the paper. If the raw material is virgin wood pulp, the dust level is no problem. However, if recycled paper is used as raw material, and the process is not appropriate, the dust level is difficult to meet the standard. Then the ash after burning is easy to stick to a piece, and if it is a paper towel made of pure wood pulp, the ash is relatively clean and not sticky.

9、Hole

The hole index is the limit on the number of holes on the wrinkle toilet paper, the hole will have an impact on the use of paper, too many holes of the wrinkle toilet paper is not only poor appearance, but also easy to damage in use, affecting the wiping effect.

Bamboo pulp facial tissue

Bamboo pulp facial tissue